A mechanical process of imprinting images on glass in which the surface of glass is roughened using a high pressure jet of abrasive material (sand or corundum). The abrasive material removes the outer surface of glass, which results in visible matting. Special stencils allows to create intricate patterns with sharp, precise contours. With an extraordinary accuracy we are able to transfer ornaments and text onto the glass. This technique can be applied for all types of objects: doors, partitions, ceilings and also for commemorial plaques and art objects.

Sandblasted Art Glass

With longer exposure to the abrasive stream we'll obtain a Carved Glass - a three dimensional sculpted image with greater detail. Sandblasting can be apllied on layered colored glass (eg a white matte pattern on a red glass). It is also possible to glaze back the matted surface (fire polishing) which adds a smooth shiny surface to the glass.

Matted glass (etched or sandblasted) is not an invention of recent times, you can find great Art Nouveau or Art Deco examples of this technique. It turned out that this method allows also to create modern avant-guarde works, perfectly harmonizing with the architecture of our times. Combined with new digital processing methods allows us to transfer a photography onto a glass. Sandblasting can be also mixed with slumped or fused glass technique, it's perfect for lettering and logotypes.

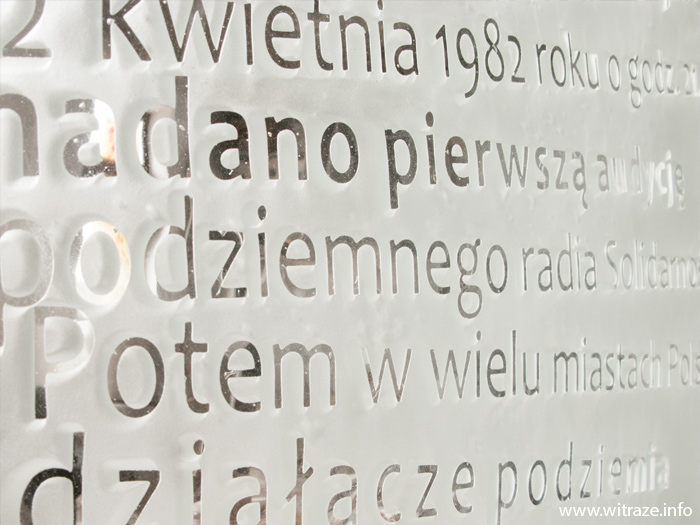

Sandblasted plaque Radio Solidarność

Sandblasted plaque Radio Solidarność

Fern leaves- two panes of sandblasted glass combined together - overlapping patterns create an interesting dimensional effect.

Fern leaves- two panes of sandblasted glass combined together - overlapping patterns create an interesting dimensional effect.

Deep sandblasting - carved glass with very sharp detail

Deep sandblasting - carved glass with very sharp detail

Size. The size of the glass panel can't exceed 1.5 m x 3 m. For larger dimesions, additional divisions should be considered.

Reinforcement. The thicker the glass the greater the durability. Sandblasted glass panels can be tempered for safety reasons.

Sandblast Glass Protection. The sandblasted surface is sensitive to dirt. To protect it, we cover it with special shields ensuring long-term use.

Project. Our projects are prepared as a digital file. Additionaly we offer to make a sample of glass to ensure the final effect.